Turkish Marble: The Global Standard for Natural Stone Excellence

The World’s Largest Natural Stone Reserve

Türkiye stands as a premier global destination for natural stone, boasting the world’s largest reserves. With an extraordinary selection of over 80 stone types and more than 650 unique colors and patterns, the diversity of Turkish stone is unmatched. From timeless classics to rare exotic varieties, Turkish marble provides architects and designers with an endless palette of creative possibilities.

Renowned Varieties and Applications

Turkish marble is celebrated for its exceptional quality, durability, and aesthetic appeal. Some of the most prestigious varieties sought after worldwide include:

Anatolia Beige & White: Elegant choices for high-end flooring and interiors.

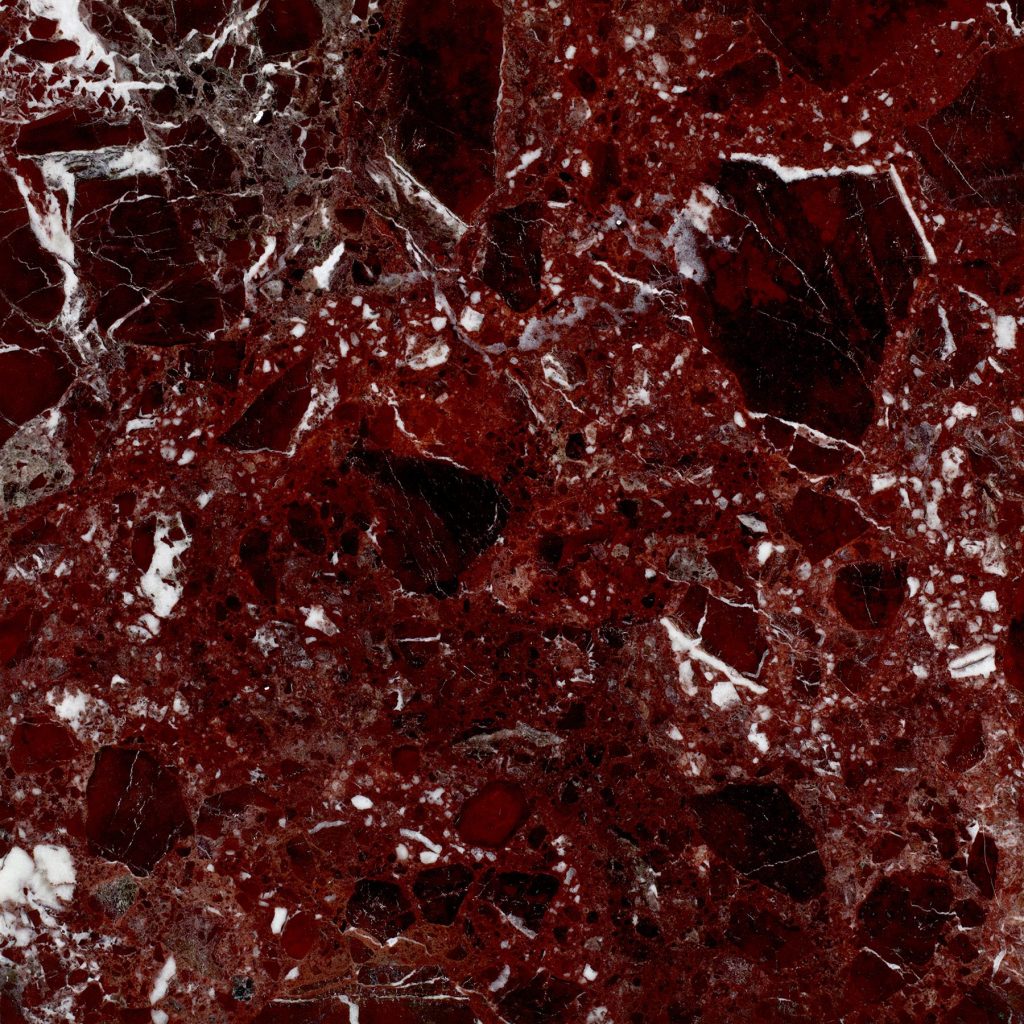

Elazığ Cherry: A unique, deep-toned stone that adds a touch of luxury.

Milas Lilac & Afyon White: World-famous selections for sophisticated architectural projects.

Marmara Marble: Historically significant and structurally robust, ideal for both classic and modern designs.

Beyond marble, Türkiye is a leading exporter of travertine, basalt, dolomite, limestone, and granite, offered both as raw blocks and meticulously processed tiles or mosaics.

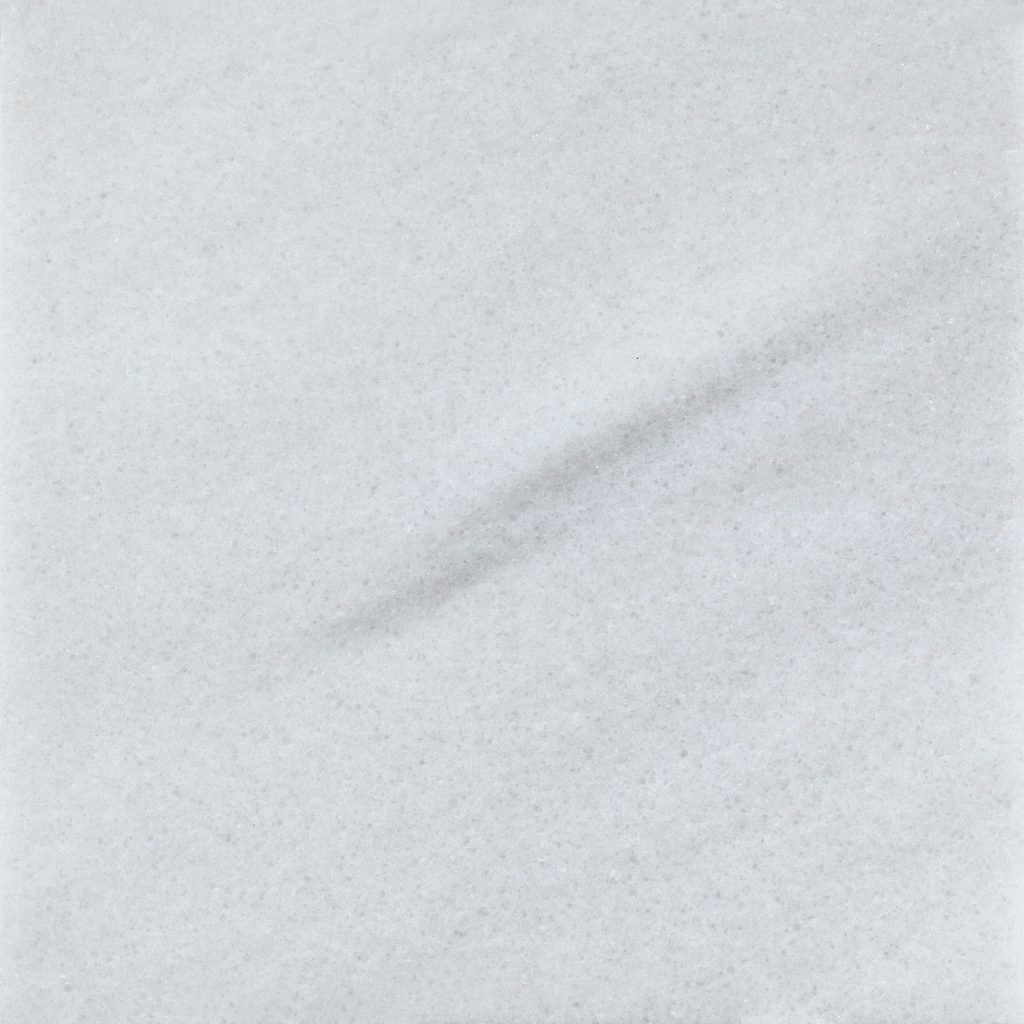

Turkish Marble Marmara White

Turkish Marble Elazığ Cherry

Turkish Marble Anatolia Beige

Turkish Marble Afyon White

From the Quarry to Perfection: The Processing Journey

Transforming raw stone into a finished masterpiece is a journey of precision and craftsmanship. This intricate process involves several critical stages:

Extraction & Slicing: Raw stone is carefully quarried and transported to advanced facilities where it is cut into massive slabs using high-tech machinery.

Polishing & Refinement: The slabs undergo professional polishing to achieve the desired texture—from high-gloss shines to matte finishes.

Precision Cutting: Specialized saws transform slabs into tiles of various dimensions, tailored to specific project needs.

Rigorous Quality Control: Every tile is inspected for imperfections and sorted by color and grade, ensuring only the finest products reach the global market.

Why Designers Choose Turkish Stone

The combination of vast reserves, advanced processing technology, and centuries of stonemasonry expertise makes Türkiye the preferred partner for international projects. Whether it is for grand building exteriors, luxury countertops, or intricate landscaping, Turkish natural stone delivers a perfect blend of durability and timeless beauty.

Contact Our Experts